Electronics Market Update 2021

Optimism Cools on Electronic Component Sales

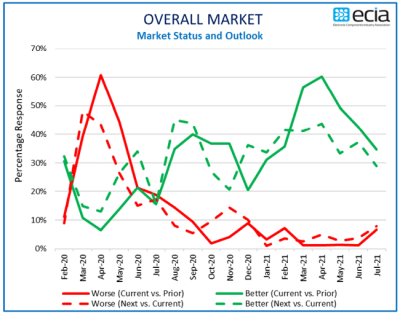

Data released by the industry’s largest distributors, Arrow Electronics Inc. and Avnet Inc., showed record component sales growth in calendar Q2 and ongoing high demand. After six months of shortages, however, customers may be more realistic about how many parts they can actually get.

Optimism Cools on Electronic Component Sales

Data released by the industry’s largest distributors, Arrow Electronics Inc. and Avnet Inc., showed record component sales growth in calendar Q2 and ongoing high demand. After six months of shortages, however, customers may be more realistic about how many parts they can actually get.

Optimism Cools on Electronic Component Sales

Data released by the industry’s largest distributors, Arrow Electronics Inc. and Avnet Inc., showed record component sales growth in calendar Q2 and ongoing high demand. After six months of shortages, however, customers may be more realistic about how many parts they can actually get.

Optimism Cools on Electronic Component Sales

Data released by the industry’s largest distributors, Arrow Electronics Inc. and Avnet Inc., showed record component sales growth in calendar Q2 and ongoing high demand. After six months of shortages, however, customers may be more realistic about how many parts they can actually get.

Optimism Cools on Electronic Component Sales

Data released by the industry’s largest distributors, Arrow Electronics Inc. and Avnet Inc., showed record component sales growth in calendar Q2 and ongoing high demand. After six months of shortages, however, customers may be more realistic about how many parts they can actually get.

Optimism Cools on Electronic Component Sales

Data released by the industry’s largest distributors, Arrow Electronics Inc. and Avnet Inc., showed record component sales growth in calendar Q2 and ongoing high demand. After six months of shortages, however, customers may be more realistic about how many parts they can actually get.

Optimism Cools on Electronic Component Sales

Data released by the industry’s largest distributors, Arrow Electronics Inc. and Avnet Inc., showed record component sales growth in calendar Q2 and ongoing high demand. After six months of shortages, however, customers may be more realistic about how many parts they can actually get.

Optimism Cools on Electronic Component Sales

Data released by the industry’s largest distributors, Arrow Electronics Inc. and Avnet Inc., showed record component sales growth in calendar Q2 and ongoing high demand. After six months of shortages, however, customers may be more realistic about how many parts they can actually get.

Optimism Cools on Electronic Component Sales

Data released by the industry’s largest distributors, Arrow Electronics Inc. and Avnet Inc., showed record component sales growth in calendar Q2 and ongoing high demand. After six months of shortages, however, customers may be more realistic about how many parts they can actually get.

Optimism Cools on Electronic Component Sales

Data released by the industry’s largest distributors, Arrow Electronics Inc. and Avnet Inc., showed record component sales growth in calendar Q2 and ongoing high demand. After six months of shortages, however, customers may be more realistic about how many parts they can actually get.

Optimism Cools on Electronic Component Sales

Data released by the industry’s largest distributors, Arrow Electronics Inc. and Avnet Inc., showed record component sales growth in calendar Q2 and ongoing high demand. After six months of shortages, however, customers may be more realistic about how many parts they can actually get.

Optimism Cools on Electronic Component Sales

Data released by the industry’s largest distributors, Arrow Electronics Inc. and Avnet Inc., showed record component sales growth in calendar Q2 and ongoing high demand. After six months of shortages, however, customers may be more realistic about how many parts they can actually get.

Optimism Cools on Electronic Component Sales

Data released by the industry’s largest distributors, Arrow Electronics Inc. and Avnet Inc., showed record component sales growth in calendar Q2 and ongoing high demand. After six months of shortages, however, customers may be more realistic about how many parts they can actually get.

SHARE THIS PAGE!